Mecko

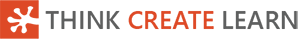

Laser cut and 3D printed parts for quick maker builds

For a while I've been searching for a prototyping system so that my students can quickly make working projects. I could never quite find anything that met my needs. So I decided to make my own! Here, you can download the CAD files for all the components. It's a work in progress, and I'm adding to the designs as the need arises.

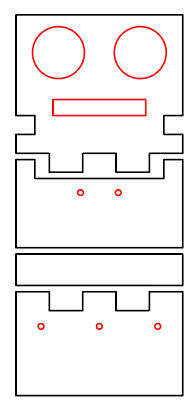

Construction Components

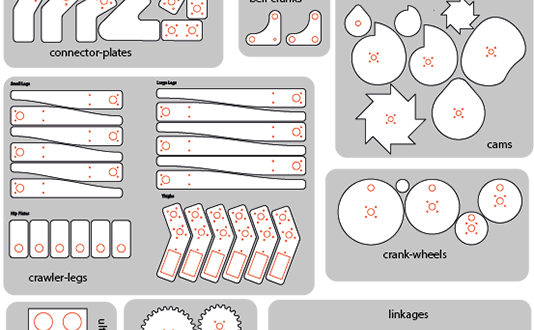

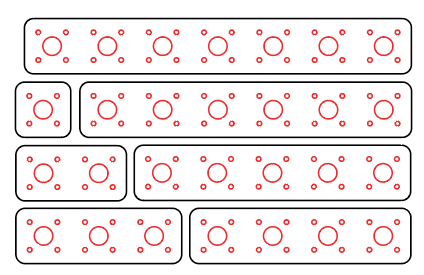

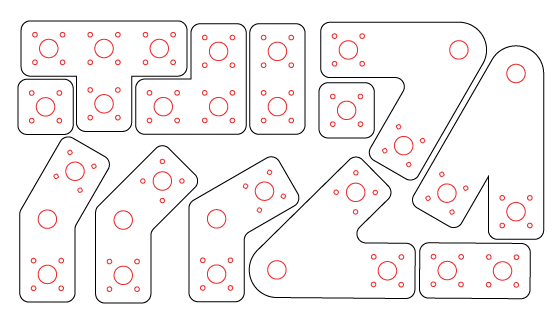

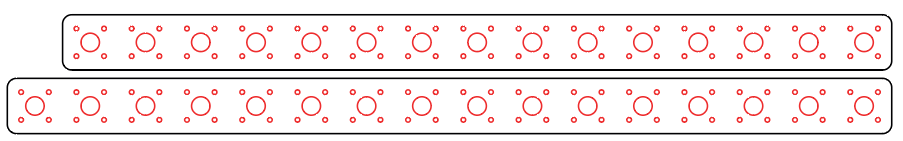

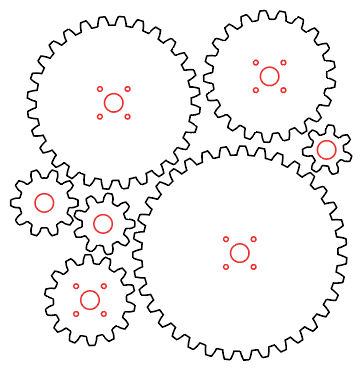

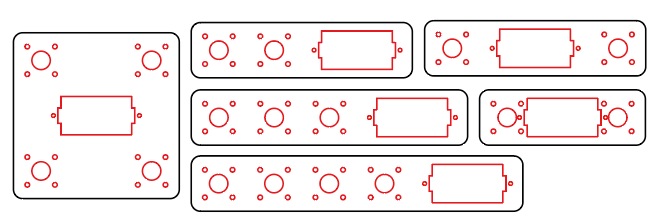

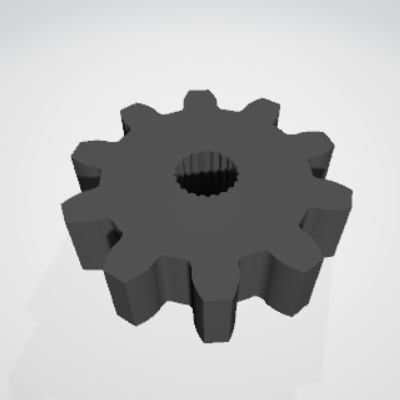

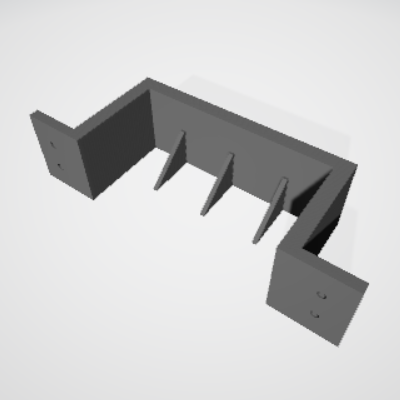

The foundation of the kit is a set of laser-cut beams, based on 3mm and 6mm plywood. This influenced the decision to base the system on 6mm units, so everything is designed to be a multiple or factor of 6. For example, the main beams are 18mm wide. In addition to straight beams, there are angled connectors, cams, gears, etc.

Here's a short video showing some of the beams.

Mecko Beams Short

Download DXF

Mecko Beams Long

Download DXF

Mecko Connector Plates

Download DXF

Mecko Beams Extra Long

Download DXF

Mecko Bell Cranks

Download DXF

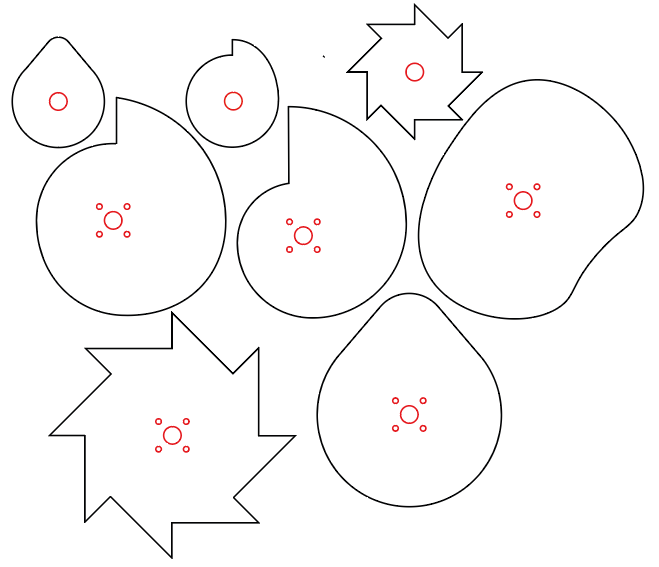

Mecko Cams

Download DXF

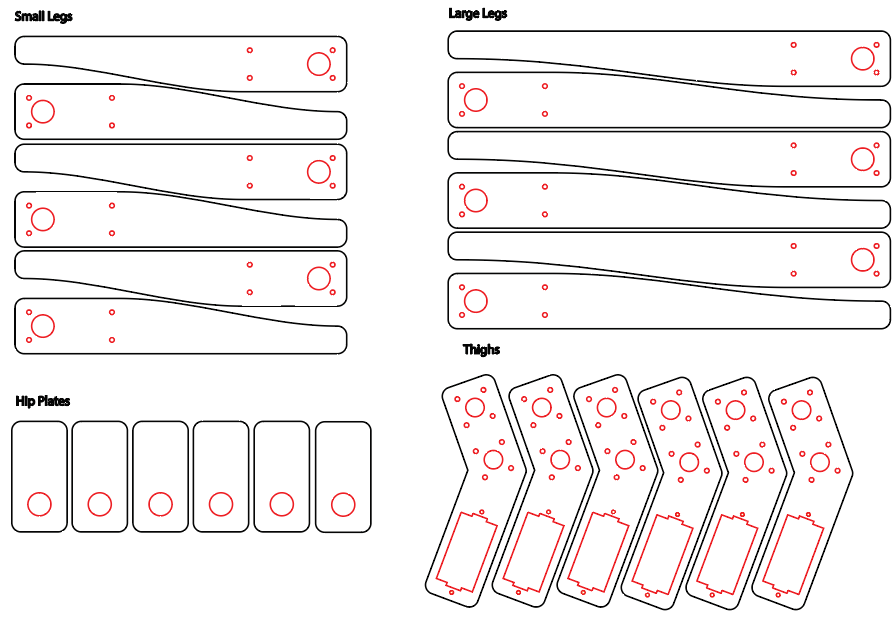

Mecko Crawler Legs

Download DXF

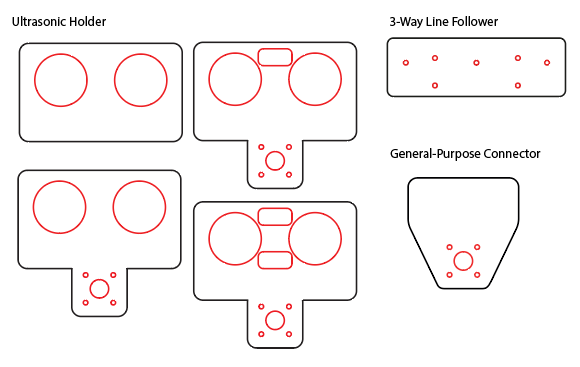

Mecko Ultrasonic Holder

Download DXF

Mecko Gears 1

Download DXF

Mecko 9g Servo Holders

Download DXF

Mecko Connector Plates Robotics

Download DXF

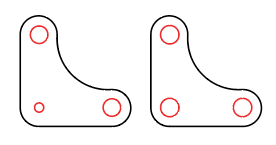

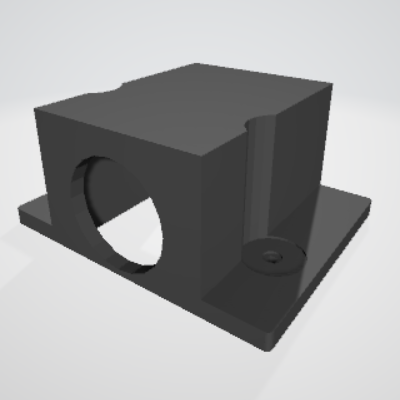

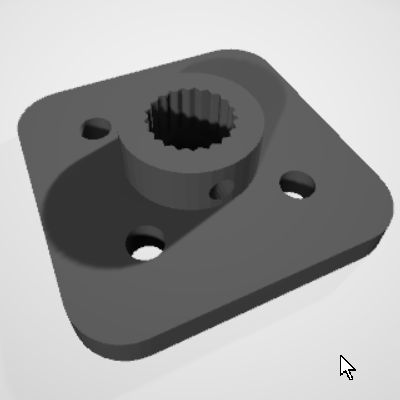

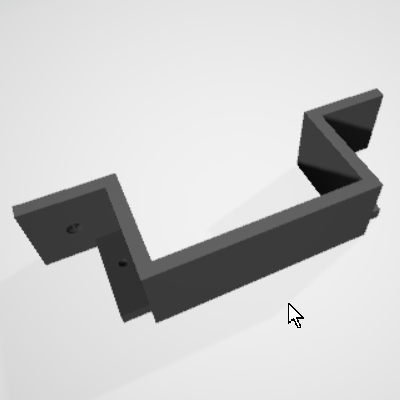

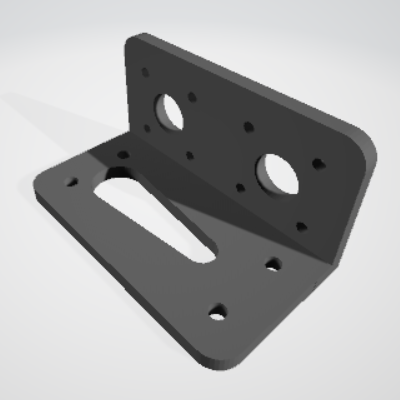

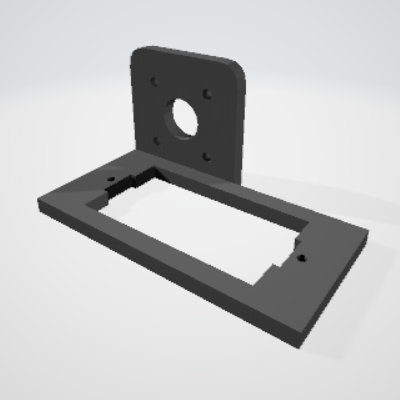

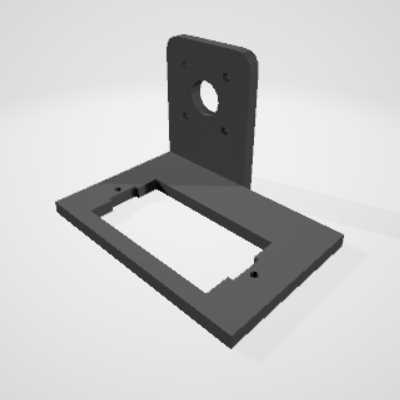

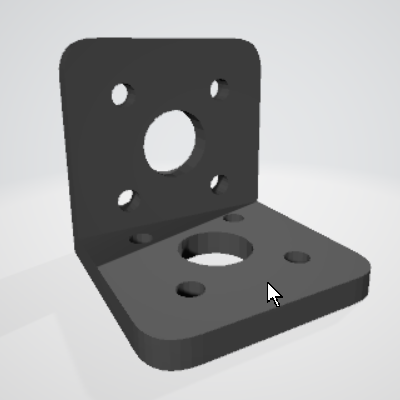

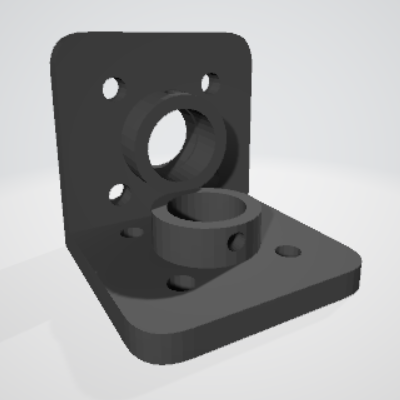

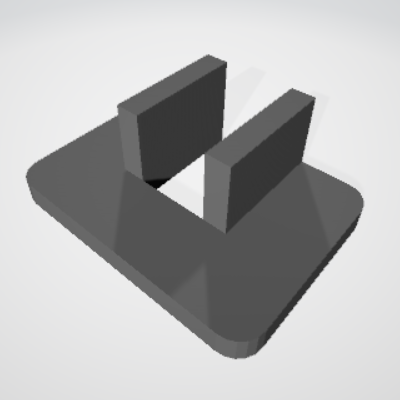

Connectors

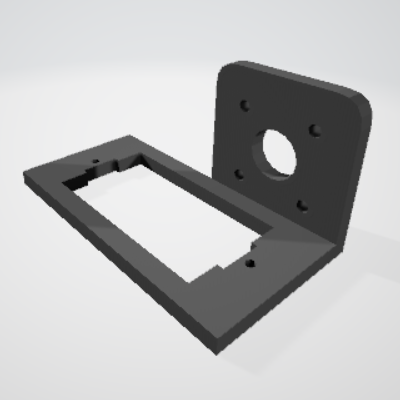

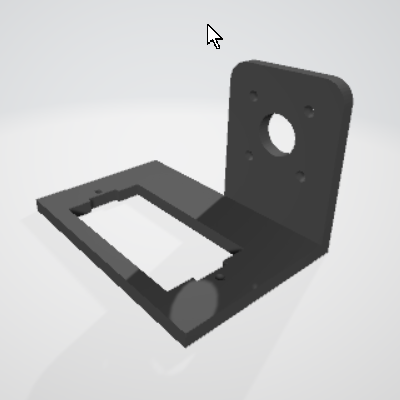

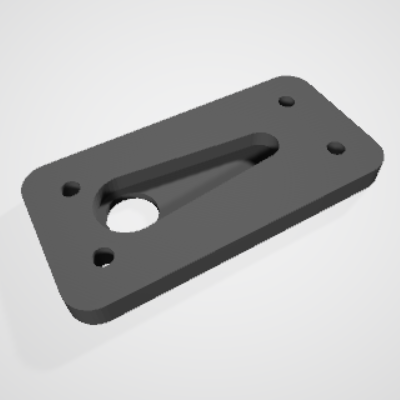

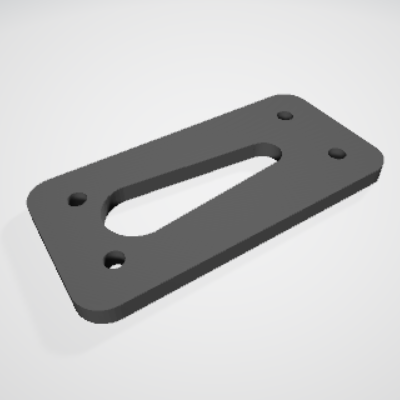

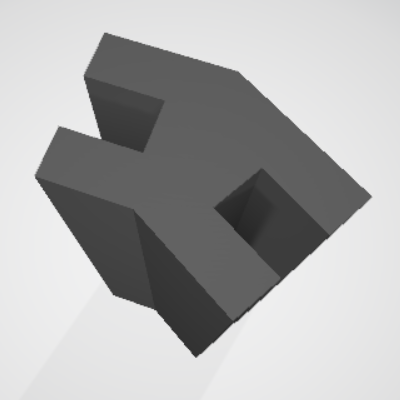

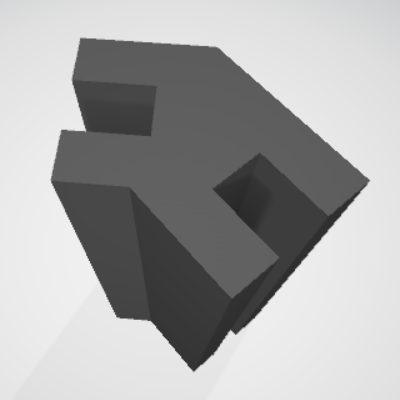

Connectors are 3D printed. Some connectors are for joining beams. In addition, a variety of connectors are available for attaching different types of motor. Click on the images to view in 3D.

Here's a short video showing some of the motor connectors.

Mecko Motor Connectors

Plate To 3mm Motor D-shaft

Download STL

Plate To 4mm Motor D-shaft

Download STL

Plate To 5mm Motor D-shaft

Download STL

Plate To 5mm Motor Double-flat-shaft

Download STL

Plate To TT Motor Double-flat-shaft

Download STL

6mm Thick Gear 10T To 3mm Motor D-shaft

Download STL

Motor M3 Face Mount

Download STL

N20 Motor Mount

Download STL

Mecko 9g Servo Connectors

6mm Thick Gear 10T To 9g Servo 21T

Download STL

Plate To 9g Servo 21T

Download STL

9g Servo Holder

Download STL

9g Servo 90 Angle

Download STL

9g Servo Hip Horn Angle Adapter

Download STL

9g Servo Holder 90 Left

Download STL

9g Servo Holder 90 Left Tall

Download STL

9g Servo Holder 90 Right

Download STL

9g Servo Holder 90 Right Tall

Download STL

9g Servo Horn Plate Retained

Download STL

9g Servo Horn Plate Retained Round

Download STL

9g Servo Horn Plate

Download STL

Mecko Full Size Servo Connectors

Towerpro Mg996 Servo Holder

Download STL

Mecko Rod and Beam Connectors

Plate To Plate 90 Degrees

Download STL

Plate To M3 Rod

Download STL

Plate To M6 Rod

Download STL

Plate To Plate 90 Degrees M6 Rod

Download STL

Offset 6mm

Download STL

Slot 3mm

Download STL

Header Covers (for 2.54mm header pins found on circuit boards)

Header Pin Block Cover 2x4

Download STL

Header Pin Block Cover 3x4

Download STL

Sensor Holders

Ultrasonic Connected

Download STL

Ultrasonic Joiner 30

Download STL

Ultrasonic Joiner 45

Download STL

Ultrasonic Plain

Download STL

Note that different 3D printers have different characteristics, so you may need to adjust the STL files a little, particularly the size of the holes. I sometimes need to file down or drill out holes after printing.

Screws, Bolts, etc

Standard M6 bolts can be used to connect through the large holes in the beams. These can be purchased from numerous places, such as Screwfix:

12mm bolts

16mm bolts

20mm bolts

Nuts

Flat washers

Split ring washers

Orbital Fixings do a good range of nylon M6 bolts such as these:

Small no 2 gauge screws can be used in the small holes.

The best place I have found to get these very small screws is Model Fixings.

Part no MF-ST09 is perfect for attaching the 3D printed connectors to the beams.

Parts MF-ST10 (9.5mm), MF-ST13 (12.7mm) and MF-ST08 (16mm) are longer ones which are useful for beam-to-beam connections.

Part no MF-ST30 are really tiny screws (gauge 0) which are great for attaching servo horns to the beams.

Whilst at Model Fixings, pick up a set of Draper Precision screwdrivers (part MF-DR6). These are much easier to use than the little metal jeweller's screwdrivers that seem to be the norm for small screws.

Off-the-Shelf Alternatives

There are a number of maker construction kits out there, which serve different purposes and markets. I haven't used them all, but here is a list of those I know about. Do let me know if you find others!

- Totem

System based on 10x10mm plastic beams

- MakerBeam

System based on 10x10mm aluminium beams

- MakerBeam XL

System based on 15x15mm aluminium beams

- 8020

A more industrial quality system, with 40x40mm beams, T-slots, and lots more

- Makeblock Makerspace

Educationally focussed system, with lots of parts, including their own bespoke electronic components

There are also robotics systems such as Lego Mindstorms, Vex, etc out there. I generally steer clear of these as I don't want to be lock into their ecosystem.

Lasercut File Conventions

I'm using LaserCut 5.3 on a HPC 3060 laser cutter. I use the following colour schemes:

- Green - Etch

- *Red - Inside cut

- *Black - Outside cut

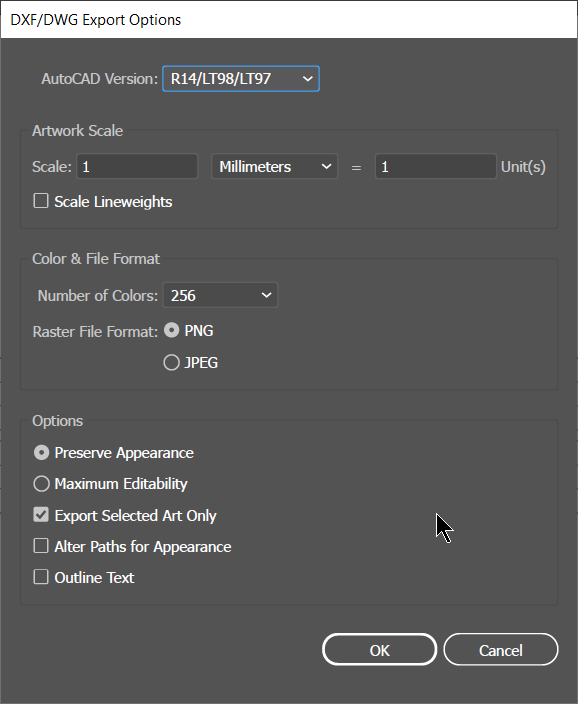

The original files were created in Adobe Illustrator. The line thickness was set to 0.25pt. The files were exported from AI using the following settings:

I set the LaserCut software to cut the above colours in sequence, so etching first, then the inside cut, then finally the outside cut. This ensures the piece is only fully cut and falls out once the etching and inside cuts are done. If you don't do this the etching and inside cuts will be misaligned!